Introduction

The recycling of plastics is encouraged worldwide and new products made from recycled plastics have been developed under governmental policies giving incentives for recycling plastics. However, engineering processes in recycling and products from recycled plastics may cause other environmental problems such as the release of contaminants during recycling processes or from the recycled products. Chemical additives or residual catalyses in recycled plastics may migrate to the environment. For example, a few studies have shown that the release of antimony and other metals from recycled polyethylene terephthalate plastic bottles may cause health concerns [1-3]. However, the effects of chemicals from recycled plastic products on human and ecosystem health are rarely investigated.

It is generally believed that recycled plastic products contain more impurities and potentially more chemical contaminants such as metals than those manufactured from plastic pellets without recycling [1,4]. Under the Korean act on the promotion of saving and recycling of resources [5], it is required to evaluate the usage and methodology of plastic recycling before the recycling process and the resulting product is approved by the Ministry of Environment. However, this regulatory process experiences difficulties in implementation due to the lack of standardized methods for evaluating the environmental impact caused by recycling processes and products. The current guideline for environmental risk assessment of chemicals in Korea does not specify the method of estimating predicted environmental concentration by using recycled products.

In this study, we propose a methodology for environmental risk assessment of hazardous chemicals that might be released to the environment from recycled plastic products. Slope protection blocks were chosen as the model recycled plastic products and four chemicals, di-(2-ethylhexyl) phthalate (DEHP), diisononyl phthalate (DINP), cadmium (Cd), and lead (Pb), were chosen as model contaminants, because phthalate esters are normally included in polyvinyl chloride plastics as plasticizers [6-8] and cadmium and lead are typical heavy metal elements found in many plastic products [9-11]. Two exposure models were built for the soil compartment under the blocks and a hypothetic stream nearby receiving runoff water. Based on the predicted no-effect concentrations for the selected chemicals and exposure scenarios, the maximum allowable emission rates from the recycled plastic blocks were also derived.

Materials and Methods

Exposure Models

Chemicals released from slope protection blocks may affect both soil and water environments. In order to evaluate the potential environmental impact of chemical contaminants from slope protection blocks, two exposure models - soil and stream models - were built.

Soil Model

Figure 1A shows a schematic diagram of the chemical transport processes in the soil model. Because the chemicals released from slope protection blocks are mobilized by water, infiltration and leaching are considered the most important processes determining the fate of chemicals in the soil. Assuming phase equilibrium between soil and pore water, for a given box of the soil compartment below the slope protection blocks, a simple mass-balance equation is as follows: where ρsoil is the density of soil (kg/m3), Vsoil is the volume of the soil compartment (m3), Csoil is the concentration of a chemical in the soil (mg/kgsoil), t is time (sec), rleaching is the vertical leaching rate of water (m/sec), A is the area of the soil compartment (m2), Cleaching is the concentration of the chemical in the leachate (mg/m3), Ksw is the equilibrium partition coefficient of the chemical between the soil and pore water (m3/kg), and k is the pseudo-first-order degradation rate constant of the chemical (sec-1). Assuming steady-state and negligible degradation of the chemical in the soil compartment, equation (1) was simplified and Csoil was calculated as follows:

Stream Model

Slope protection blocks are usually built on the cut slope near a small stream. Figure 1B shows a conceptual diagram of the runoff water flowing into the stream over the slope protection blocks. For a stream segment receiving the runoff water, a simple mass-balance equation for the concentration of a chemical in the water (Cwater) is as follows: where Vwater is the volume of water in the stream segment (m3), rrunoff is the loading rate of the chemical to the stream segment due to the chemical leaching from the slope protection blocks (mg/sec), Q is the volumetric flow rate of water in the stream segment (m3/sec), and Cstream is the background concentration of the chemical in water flowing into the segment (mg/m3). Assuming steady-state and that Cstream is negligibly smaller than Cwater, Cwater is calculated as follows:

In order to estimate rrunoff, conservative assumptions were made. The chemical loading rate to the stream (in mg/sec) can be calculated by multiplying the precipitation rate over the area of the slope protection blocks (Qprecip, m3/sec), runoff coefficient (K, dimensionless), and the concentration of a contaminant in the leachate (Cleaching) (equation 5).

Derivation of the Allowable Cleaching Based on Risk Assessment

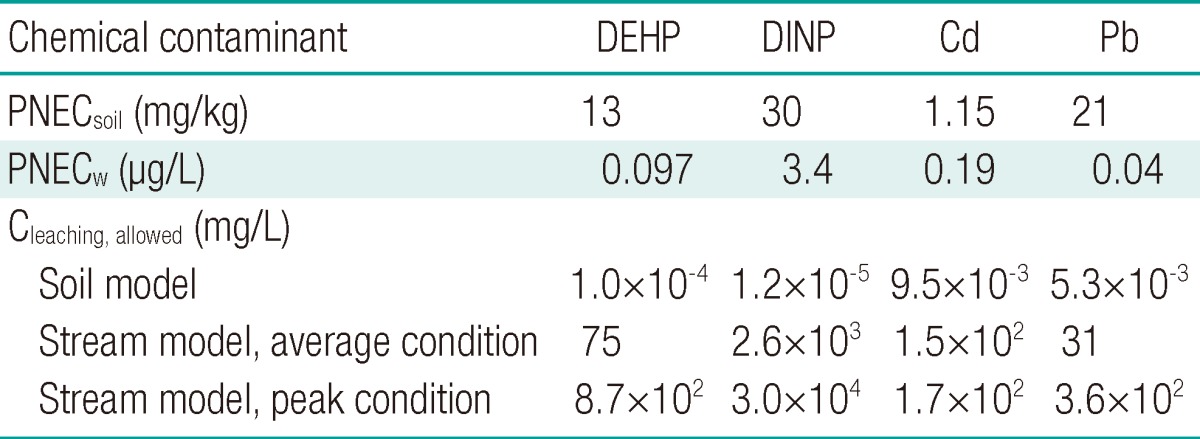

For the four model chemicals, predicted no effect concentrations (PNECs) were taken from the European Union risk assessment reports on existing chemicals [7,8,12,13]. An environmental risk quotient is calculated by dividing predicted environmental concentration (PEC) by the PNEC. In this study, Csoil and Cwater were used for the PEC. However, these values could not be calculated due to the limited information about Cleaching and rrunoff. Values of Cleaching or rrunoff could be obtained by laboratory leaching tests or field measurements. Without experimentally measured values, we used the PNECs in the soil or in stream water to derive the allowable concentration in the leachate (equations 6 and 7).

Results

Assessment of Model Parameters

Soil Model

Although various parameters are included in equation (1), the only required parameter for the assessment of the allowable leaching concentration is Ksw. For cadmium and lead, Ksw values were taken from the literature [14,15], as shown in Table 1. The values of Ksw for two phthalate esters were estimated using the hydrophobic sorption hypothesis, in which the sorption of hydrophobic organic chemicals to soil phase is dominated by soil organic carbon [16]: where foc is the fraction of organic carbon and Koc is the partition coefficient between organic carbon and water (L/kg). The value of foc was assumed to be 0.01, as suggested by Chiou and Kile [17]; the values of Koc were estimated from Kow values [6,18] using the following relationship [19]:

Stream Model

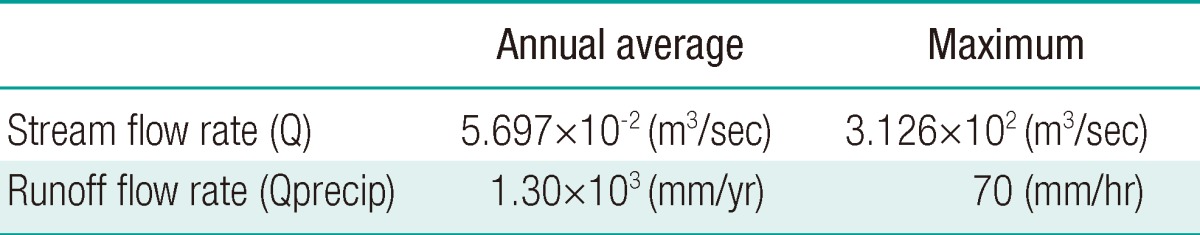

As described in equation (4), two parameters (rrunoff and Q) need to be evaluated in the hypothetic stream. Because there are large variations in precipitation rate and volumetric flow rate of a stream in Korea [20,21], the annual average and peak values for the two parameters were used. For this purpose, we estimated the model parameters using small tributary streams of Gapyeong Stream, one of the biggest tributary streams to the North Han River, as model streams. Gapyeong main stream is a typical local river containing 13 branch streams. We collected basic data to calculate average values of Q under annual average and peak conditions in the Report of Basic Plan for the Gapyeong Stream (Table 2) [22] and deducted one main stream and four branches according to "Article 2 of the enforcement decree of the Small River Maintenance Act" [23].

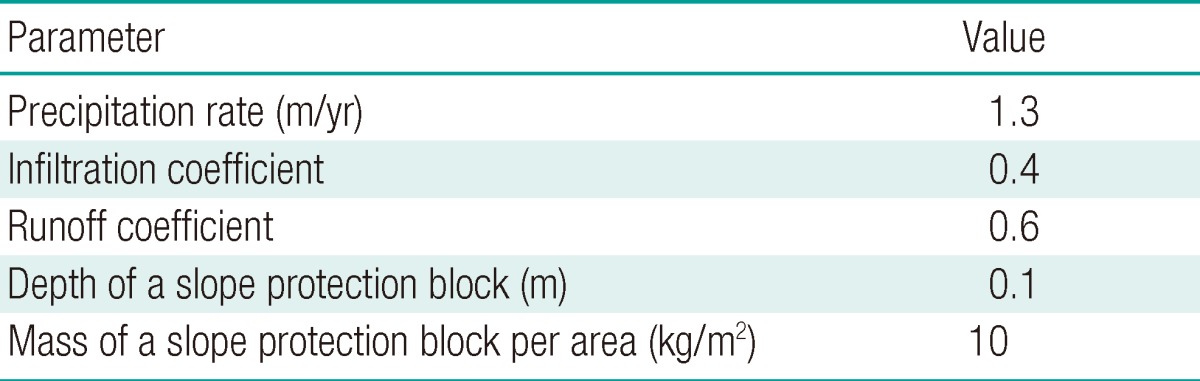

Qprecip was identified based on the rainfall intensity over the past 30 years, from 1981 to 2010 [21,24]. The annual average and maximum precipitation rates were approximated to be 1300 mm/yr and 70 mm/hr, respectively. The land area covered by slope protection blocks was assumed to be 3000 m2. Because the runoff coefficient for stiff slopes is 0.4 to 0.6 [24], 0.6 was used for conservative assessment. Because Qprecip can be calculated by multiplying the precipitation rate, covered area, and runoff coefficient, the values of Qprecip were obtained under the annual average and intensive rain conditions (Table 2).

Allowable Cleaching Based on Screening Risk Assessment

Table 3 shows the PNEC values for the soil compartment and the hypothetic stream and calculated allowable Cleaching values. The allowable levels of the four selected contaminants ranged from sub microgram to 10 micrograms per liter using the soil model. On the contrary, those using the stream model were more than a few orders of magnitude higher. This indicates that the risks posed by chemical contaminants leaching from slop protection blocks and similar construction materials would be higher in the soil compartment compared with those in the water compartment. Thus, the refined assessment with measured concentration of chemical contaminants should focus on the levels of chemicals in the soil in direct contact with those materials.

Assessment of Allowable Content of Contaminants in Recycled Slope Protection Blocks

Because the use of total content of contaminant in a recycled product is more useful in current regulations, we developed a plausible worst-case scenario for the derivation of the allowable content of the four model contaminants. In this scenario, we assumed that all contaminants in the slope protection blocks migrated in 1 year. The parameters assumed in this scenario are summarized in Table 4. Using these parameters, the volume of leachate per mass of slope protection blocks was 52 L/kg. Using the allowable Cleaching values from the soil model in Table 3, the allowable contents were derived as 5.2×10-3, 6.0×10-4, 5.0×10-1, and 2.7×10-1 mg/kg for DEHP, DINP, Cd, and Pb, respectively.

Discussion

Although the screening risk assessment used for the derivation of the maximum allowable concentrations of chemical contaminants in the leachate from slope protection blocks has limitations, it would provide a useful systematic approach for regulatory decisions. The values listed in Table 3 could be used for comparison with those values obtained from a standardized leaching test at an environmentally relevant pH. If the experimentally measured concentration of a contaminant in a laboratory leaching test is lower than the allowable Cleaching obtained by the risk assessment procedure used in this study, the use of the recycled plastic product could be regarded as not to cause significant harmful effects on the environment. In the opposite case, the use of the recycled product should not be allowed at this screening level assessment, and requires further refined assessment.

The migration of metals and other additives such as plasticizers from manufactured plastic products is of significant concern and the rate of migration strongly depends on the properties of the plastic because the diffusion coefficients of small chemicals in the plastic phase varies by more than a few orders of magnitude [25-27]. Thus, the approach exemplified in this study to deduce the allowable content of contaminants in the manufactured products should be used with great care.

In conclusion, the systematic ecological risk assessment approach used in this study for slope protection blocks as example recycled plastic products would be useful for regulatory decisions for setting the allowable emission rates or the content of chemical contaminants in a recycled product, although the method needs refinement and assumptions need to be validated further.