Preliminary characterization and probabilistic risk assessment of microplastics and potentially toxic elements (PTEs) in garri (cassava flake), a common staple food consumed in West Africa

Article information

Abstract

Garri from cassava is one of the most consumed foods in West Africa, hence this research was conducted to examine microplastics (MPs) and potentially toxic elements (PTEs) in garri from Nigeria (West Africa) and Japan. This is the first investigation on MPs in garri samples that has been reported in the literature. The study analyzed both packaged and unpackaged vended garri samples using microscopic/spectroscopic and X-ray fluorescence techniques for MPs and PTEs respectively. Microplastic particles in the garri samples ranged from (or were between) 2.00±2.00 – 175.00±25.16 particles/50 with > 90 % as fragments and consisted of polyacrylamide, polyethylene terepthalate, polyvinyl alcohol, high density polyethylene, polyvinyl chloride acrylonitrile, polyethylene chlorinated, polypropylene with silicate mix, polychloroprene and polyethylene chlorosulphonated. The mean concentration of PTEs raged from ND to 0.07 mg/g for Cr and Mn, 0.73 to 5.63 mg/g for Fe, ND to 0.57mg/g for Co, 0.23 to 1.21 mg/g for Ni, 0.15 to 1.53 mg/g for Cu, and 0.12 to 0.63 mg/g for Zn. However, their daily intake was low for both adult and children as with the MPs. The sources of MPs and PTEs were mainly from the garri production processes, atmospheric dusts and during packaging. The non-carcinogenic risk for all samples was low for MPs while in openly vended garri, Ni and Cr in all sample poses carcinogenic risks. There is a need to improve indigenous garri processing techniques to minimize contamination. This research emphasizes the critical necessity to understand the consequences of MPs on human health.

Introduction

Cassava (Manihot esculenta) is a South American plant farmed as a staple crop in tropical and subtropical parts of Africa and Asia for its edible starchy tuberous root, which is a significant source of carbohydrates [1]. Cassava is one of the most abundant sources of calories in the tropics, making it a key staple food in the developing world. After two years of decline, the worldwide cassava market climbed by 0.4 percent to $164.1 billion in 2019 [2]. Nigeria (61 million tonnes), the Democratic Republic of the Congo (32 million tonnes), and Thailand (32 million tonnes) consumed the most cassava in 2019, accounting for 42 percent of world consumption. Ghana, Brazil, Indonesia, Angola, Vietnam, Cambodia, Mozambique, China, and Malawi trailed with 37 percent of the total consumption. Ghana (646 kg per person), Cambodia (572 kg per person), and Angola (494 kg per person) had the greatest amounts of cassava consumption per capita in 2019 [2].

The high consumption of cassava in Africa is associated with high garri consumption (cassava flakes) and other cassava products such as tapioca, lafun, fufu, starch and attieke [3]. Garri, is a dry, crispy, creamy-white or yellow, granular flour obtained from cassava roots [4]. It is a well-developed and convenient staple food commodity produced from cassava in West Africa. İt is found to be a reliably food substance from past generations and still trending due to its relatively low cost when compared to other sources of carbohydrates in flour forms, ease of handling and manufacture due to its light weight and ease of transportation [5]. It is often eaten raw with water, sugar, groundnuts, and cashew nuts added, or baked into a dough called eba—the most popular form—or sprinkled over cooked cowpea beans in several African nations such as Nigeria, Togo, and Benin Republic [6]. Given that garri is predominantly eaten in low-income nations, where it is an inexpensive and vital diet component, it will continue to increase. People are more prone to minimize consumption of costly foods in the face of economic hardship and civil crisis while maintaining the major diet element. This, together with high population growth rate will continue to drive up garri consumption in the future.

The production process of garri from cassava in Africa has been based on traditional methods and thus very prone to contamination by potentially toxic elements (PTEs) and microplastics (MPs). A flat iron sheet pierced with nails and connected to a wooden board is used as the traditional cassava grater [1]. The peeled roots are rubbed against the sharp perforated surface of the iron sheet, which grinds the root into the mash. Blood streaks in the grated cassava are typical as a result of bruising or injury to the processor’s hands. To press out the extra moisture from the grated mush, stones and sometimes knotted timbers are employed, although pressers are also utilized in certain regions. The roasting procedure is then carried out using iron or earthenware pans and firewood as a source of heat [7]. Furthermore, partly roasted gari is dried entirely in the sun without taking into account pollutants from driving automobiles and the atmosphere [8]. The produced garri are often exported to other countries where Africans are residents [5,9].

PTEs are naturally occurring substances in the environment, and their toxicity is determined by their concentration rather than their existence [10]. There have been many reports on the present of PTEs in local garri samples [7,8,11]. Sixty-one distinct garri samples from different counties in Liberia were analysed by Awoyale [7]. They observed that the mean concentrations of iron (Fe), copper (Cu), zinc (Zn), and aluminium (Al) in the garri samples were 43.87 mg/kg, 0.94 mg/kg, 5.49 mg/kg, and 257.45 mg/kg, respectively. Yellow gari had the lowest Al level, but the highest Fe (64.90 mg/kg), Cu (1.25 ppm), and Zn (7.85 mg/kg) contents (87.15 mg/kg). Groundnut-moringa-fortified garri had lower Fe content (42.93 ppm), Cu content (0.70 ppm), and Zn content (3.50 mg/kg) than unfortified garri. Their samples and counties had no statistically significant impact (p >.05) on the goods’ heavy metal content. Lovet [11] assessed the health risks associated with a number of heavy metals present in garri sold in a number of significant markets in the Nigerian city of Yenagoa. The results showed that the concentrations of these heavy metals ranged from 1.32 to 3.81 mg/kg (manganese), 2.21 to 5.66 mg/kg (zinc), 1.00 to 3.72 mg/kg (copper), and 11.16 to 38.75 mg/kg (copper) (iron). In each of the heavy metals, they discovered a significant difference (P0.05) between the various sites. The health risk index value and goal hazard quotient were both 1. This suggests that the community under research is not at danger for any health effects from the examined heavy metals in the garri. Magnesium, potassium, calcium, manganese, iron, and cobalt were found in white and yellow garri that were processed in the Ijebu region of Nigeria, according to Erukainure [42]. However, studies of global implications are required to properly evaluate the levels and risks of consuming PTEs from garri consumption. Additionally, there are no prior study of the presence of MPs in garri and this study intends to fill this knowledge gap.

MPs are plastic particles with a length of less than 5 mm (0.20 in) [12]. The growing body of data on MPs has shown that they are frequently incorporated into foods as contaminants from environment [13,14], during manufacture and processing [15,16] and/or contamination by plastic packaging [17]. Reports show that MPs (< 130 μm) have the potential to translocate into human tissues, elicit localized immune response, release constituent monomers and toxic chemical additives used in plastic production, as well as pollutants adsorbed from the environment such as heavy metals [18] and organic compounds [19]. There is high possibility of contamination of garri due to limited knowledge about material handling by the processors.

The presence of PTEs and MPs in garri may pose double danger to the consumer as MPs in garri possess the ability to adsorb PTEs [72, 73]. Therefore, the aim of this study was to investigate the occurrence of MPs and PTEs in packaged and unpackaged garri samples from Nigeria and Japan. Findings from this study may also be extended to processing units in other countries that manufacture garri on a large scale. The specific objectives include (1) quantify and characterize MPs presence in garri; (2) determine the concentrations of selected PTEs in garri (3) identify the sources of both MPs and PTEs using multivariate statistical techniques including principal component analysis (PCA) and hierarchal cluster analysis (HCA). (4) evaluate the estimated daily intake, carcinogenic and non-carcinogenic risks of MPs and PTEs to adult and children from garri consumption. This study is expected to fill the knowledge gap on the health risks associated with MPs and PTEs in garri and therefore provides the first data on MPs risks estimation from garri consumption. Risk assessment is critical since it is an essential aspect of occupational health and safety management. These will assist to identify the need for garri process and handling regulations and reduce the possible health risks linked with the presence of PTEs and MPs in garri from consumption.

Materials and Methods

Chemicals and materials used

All solutions were prepared using ultra-pure water (resistivity of 18 MΩ cm) provided by a Direct Q-3UV, (Merck KGaA, Darmstadt, Germany). The density separation salt (NaCl) solutions were filtered through a Whatman® GF/A microfiber filters (0.45 μm pore; diameter of 47 mm). All analytical glassware was acid cleaned and thoroughly rinsed with pre-filtered ultrapure water before to use.

Sample collection

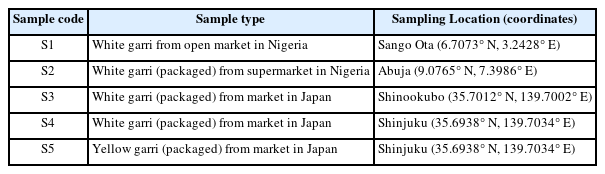

The garri samples used for this study were collected from two countries; Nigeria in West Africa and Japan in East Asia for comparison. The sampling summary is presented in Table 1. Two samples (S1 and S2) were collected in Nigeria and three (S3–S5) in Japan totaling five composite samples. Two garri samples were collected from Nigeria; one from open market in Ota, Ogun state and the other from a supermarket in Abuja, Nigeria’s capital. The samples collected from the local market were kept in in sterile Ziploc bag before transporting to Japan for the study (Ziploc bags were analyzed to be sure it didn’t contaminate the samples). These two sources were considered since it covered the two ways garri are globally packaged for global market (Figure 1). The other three samples were collected from halal shop in Shin-Ōkubo and Shinjuku (ordered online) in Tokyo, Japan respectively. The package weight of all samples was 5 kg except for yellow garri (1 kg). These samples were packaged similarly as shown in Figure 1b. The garri samples sold in Japan were mainly imported from West Africa [20]. To acquire the mash samples, cassava is peeled and grated in a locally constructed motorized cassava grating equipment, then fermented for 48 hours before dewatering using a manual screw press. The granular particles were fry-toasted to white garri after the compressed mash samples were released from the pressing machine and sorted through a woven cane-mesh [1]. The same production methods apply to yellow garri, but the granules are mixed with palm oil before fry-toasting or roasting. During the production processes, garri can easily be contaminated by MPs and toxic elements.

Sample preparation

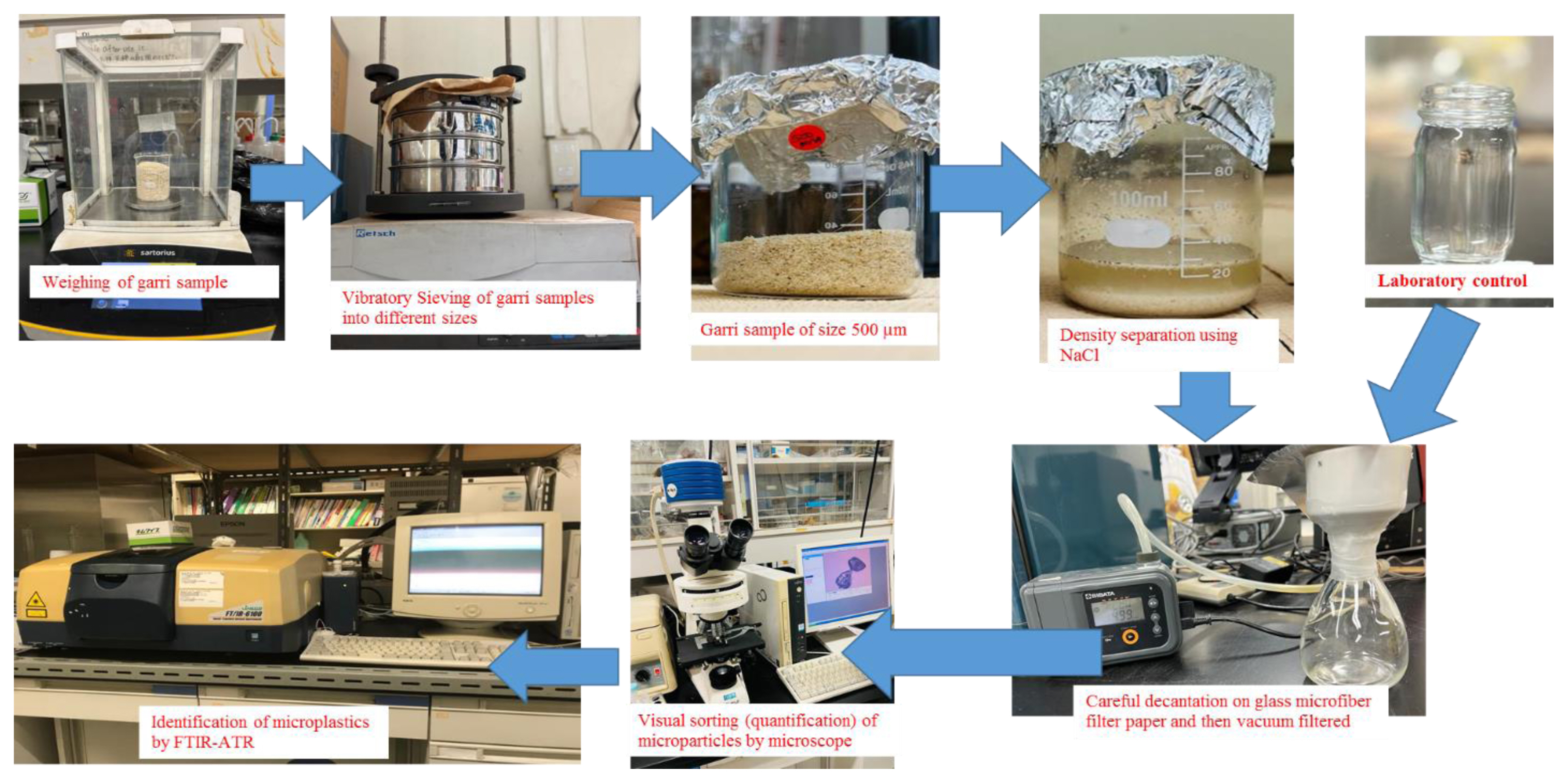

The garri samples were oven dried at 105 ºC to constant minimum moisture content for 6 hours. This was done to ensure the samples were properly dried. At the heating temperature, the potential impact on the polymers will include degradation within the garri matrix [76]. However, the amount of polymer particles within the sample may not be influenced. Chamas [77] explain that during degradation of MPs particles in environmental matrix, the degradation only decreases the original mass without affecting the overall quantity of plastic present. This temperature is high than some of identified polymer glass transition temperature such as PMMA, PET etc and thus the state of the polymer may change from a hard/glassy state to a soft/leathery state, or vice versa [78, 79]. However, since in this study, the MPs were analyzed based on quantity and not mass this effect can be ignored, as it will have negligible impact on the results. Fifty grams (50 g) from each garri samples were weighed in a beaker using Mettler Electronic Balance (ME103E, U.S.A). The samples were then sieved to micro size of 500 μm using the Vibratory Sieve Shaker for 30 mins at 60 Hz (Retsch AS200, Japan) (Figure 2). The preparation and analysis for each sample was done in triplicates.

Analytical methods

Microplastics extraction and characterization

This study is the first to investigate the presence of microplastics (MPs) in Garri samples. In order to analyze the samples, a modified method for analyzing MPs in another matrix [22] was used. The process involved taking a sample of Garri, breaking it down to a size of 500 μm, and transferring it into a beaker. Next, a solution of NaCl (1.2 g/cm3) was added to the beaker and the mixture was stirred for 5 minutes. After 30 to 60 minutes, the solution was filtered to separate the heavier materials from the lighter ones. The choice of NaCl was due to the density of Garri which could range from 1.24 to 1.51 g/cm3 [23, 74], as this will enable the microplastics to float while the Garri particles sink. To collect floating plastic particles, the supernatant water was filtered using a Millipore vacuum pump onto Whatman® GF/A microfiber filters (0.45 μm pore; diameter of 47 mm). The filters were dried overnight in a covered glass petri dish at room temperature.

The residues on the filter papers were visually examined with the help of a fluorescent microscope (MX6300, Meiji Techno Co. Japan). The image from the fluorescent microscope was further analyzed using Pixera INstudio software Ver.3.5.2 for shape and size. All detected/counted particles had size range of 12 to 500 μm. They were classified into microparticles (MPas) and microplastics (MPs), and those considered to be polymers (about 90 % of all particles) were analysed with ATR (Attenuated total reflectance; ATR PRO ONE Base Kit)-FTIR (Fourier-Transform Infrared) system (JASCO FTIR-6100) for functional groups for polymer classification of the MPs. The instrument was firstly blanked before using it to analyze the MPs. The MP sample was simply placed in the FTIR sample chamber for measurement. The infrared spectrum was recorded in the 400–4000 cm–1 range by averaging 64 scans at a resolution of 4 cm–1. The obtained spectra were matched with library database (OpenSpecy: https://openanalysis.org/openspecy/) for identification of MPs types. The following MPs were identified including PAM (Polyacrylamide) with correlation coefficient (r) = 0.7; PET (Polyethylene Terepthalate) with r = 0.75; PVA (Polyvinyl alcohol) with r = 0.81; HDPE (High density polyethylene) with r = 0.75; PVC-A (Polyvinyl chloride acrylonitrile) with r = 0.61; PE-C (Polyethylene chlorinated) with r = 0.65; PP-S (Polypropylene with silicate mix) with r = 0.75; PCP: (Polychloroprene) with r = 0.65; and PE-CS (Polyethylene chlorosulphonated) with r = 0.65.

Particle extraction and all tests were carried out within a laminar flow chamber to prevent contamination from the air. A 100 percent cotton laboratory coat was worn during the study to avoid contamination. All glasswares, containers, beakers, filtering units, and equipment used to treat samples were washed in filtered ultrapure water (Direct Q-3UV, Merck KGaA, Darmstadt, Germany) before use. Throughout the experiment, all laboratory work benches and workspace were cleaned with 70 % ethanol. Aluminum foil was used to cover samples that were not being processed (extraction and characterization). Water utilized in particle extraction (procedural blank, C1) and water left open in the experimental lab for the duration of extraction (air blank, C2) were employed as contamination controls. These controls were analysed with the samples (Figure 2).

Potential toxic elements (PTEs) analysis

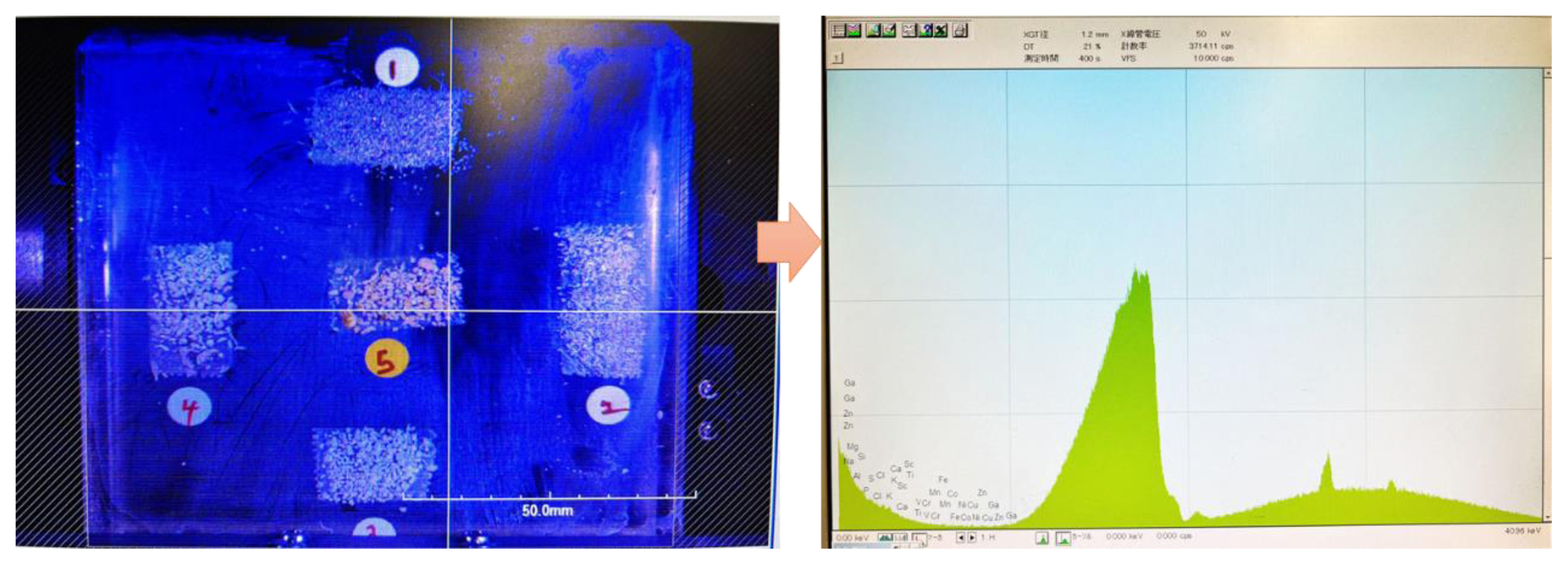

PTEs analysis was conducted directly on the dried garri samples using the XGT-5000 (Horiba Scientific, Japan) based on X-ray fluorescence analytical technique. The dry garri sample was placed on the sample holder and attached by both sides of scotch tape. After mounting sample, the sample holder was placed in the XGT. The garri samples attached on the sample holder were then analyzed using single point method. Single point analysis allows for precise quantitative and qualitative analysis, while elemental imaging produces comprehensive distribution maps for specific elements (Figure 3). The instrument was calibrated before use using certified reference material CJ-2 (CRM CJ-2), made up of simulated Asian mineral dusts (NRCREAM P.R. China and NIES, Japan). The XGT approach is based on energy dispersive x-ray fluorescence (EDXRF), which is an excellent technique for determining the elemental composition of materials quickly and without destroying them. The XGT-5000 combines this with microscopic spatial resolution to produce unique high-intensity X-ray beams ranging in diameter from 1.2 mm to 10 μm. At 10000 count per seconds and energy of 50 kV, the scan took 400 seconds.

Risks assessment

Estimated daily intake

Microplastics

Oral intake might be an individual risk route associated with human exposure to microplastic contamination of garri samples. The size of the detected MPs ranged from 12 to 500 μm, which is enough for it to ingested from consumption of garri. In addition, the size may even become smaller as the garri is chewed during consumption or when it is baked as dough (often called eba). Consequently, the estimated daily intake (EDI) attributable to exposure to MPs as a consequence of consuming contaminated garri was calculated using the equation (1) [47].

where, EDIq/p: estimated daily intake of MPs based on quantity (EDIq) and polymer type (EDIp) through consumption of garri (MPs particles/g-year or particles/g-year); Pi/mi: average quantity of the MPs in garri sample (Pi) and quantity of the different MPs types in garri sample (Pmi) (MP particles/50 g); RI: ingestion rate is (800 g per day or 292000 g per year) estimated for cassava product consumption [11], [24], [25]; BW: average body weight (70 kg or 70000 g for adults; 15 kg or 15000 g for children) as described in earlier reports [17].

PTEs

The estimated daily intake (EDI) of PTEs from the consumption of garri by adults and children was calculated using the United States Environmental Protection Agency’s health risk models [26] as described in equation (2). The C is the PTEs concentration in garri (mg/g), ED is exposure duration (70 years), EF is exposure frequency (365 days), and AT is the non-cancer average time (70x365 year).

Non-carcinogenic and carcinogenic risks

MPs polymer risk indices

The MP polymeric risk indices for the various garri samples, as well as for the overall research region, was calculated according to the preceding description [27], [28]. Formulae (3) and (4) offer the equations for calculating the polymer risks indices (pRi) for the various samples and the index (pRarea) for the study area (Nigeria and Japan). The chemical toxicity coefficient or risk scores (Sj) for the detected MPs polymers in the samples were computed using the hazard values provided based on their toxicity levels as reported by Lithner et al. [75]. PP (PP-S) = 1; PE (PE-C and PE-CS) = 11, PET = 4, HDPE = 11, PAM = 50, and PVC-A = 6957 were the hazard scores for the polymers detected in the samples, whereas PVA and PCP were not accessible and were eliminated from the calculations. pRi, on the other hand, is the number of each individual MPs polymer found in sample 1 whereas pRarea is the nth root of the polymer risks indices products.

MPs carcinogenic risks (pCR) estimation

Consumption of MPs polymers may be used to quantify the additional risk of cancer over the course of a person’s lifetime. By increasing the predicted daily/yearly consumption by a cancer slope factor (Equation 5). The cancer slope factor (CSF appears in the context of quantitative risk assessment of chemicals or compounds that are being evaluated as carcinogens [47]. It’s a metric for the likelihood of acquiring cancer as a consequence of a lifetime of exposure to a substance. The oral CSF for some polymers or precursors includes; vinyl chloride (PVC-A) = 1.9 risk per mg/kg-d (0.69 risk per mg/g-year), ethylene oxide (e.g., PE, HDPE, and PET) = 1.02 risk per mg/kg-d (0.37 risk per mg/g-year), acrylamide (PAM) = 4.5 risk per mg/kg-d (1.64 risk per mg/g-year), and propylene oxide (PP-S) = 0.24 risk per mg/kg-d (0.09 risk per mg/g-year) [29–30]. PCP and PVA were excluded because data were not available. The available CSF were used in computing MPs carcinogenic risks (pCR) assessment.

PTEs Hazard quotients

The hazard quotient (HQ) was used to estimate the non-carcinogenic effects of PTEs [26]. (Equation 7)

RfD is the maximum permitted risks determined by daily exposure to the human body [31], given as Cr = 3×10-6, Mn = 4.6×10-3, Fe = 8×10-4, Co = 2×10-5, Ni = 2×10-5, Cu = 4×10-5, Zn = 3×10-4 mg/g/d.

PTEs carcinogenic risk estimation

The LADD is the lifetime average daily dosage (mg/g/day) as specified below [31], [32]:

Carcinogenic risks associated with Cr and Ni (as recognized carcinogens) was examined in this research as presented in Equation (9). Ingestion absorption is thought to be the primary mode of exposure to these hazardous components based on known the cancer slope factors (CSF). where CSFingestion is the cancer slope factors (kg day/mg) associated with hazardous components ingested. The CSF were Cr = 0.5 and Ni = 0.91 for ingestion [26], [33], [34].

Scope and limitations of MPs risk assessment

The purpose of this study was to investigate the possible hazards posed by microplastics (MPs) in garri, with a particular emphasis on the kinds of polymers present, their concentrations, and their consumption. In addition to these variables, the MP sizes has a big impact on how harmful they might be since it impacts how bioavailable they are. However, the related danger cannot be adequately assessed because of the shortcomings in the present methodologies for small-sized MP detection. As a result, the molecule size was not taken into account when calculating risk. The outcomes of this study may be somewhat impacted by a number of limitations. First, the absence of information on the presence of MPs in processed meals constrained the risk assessment. For instance, there is presently no information available on the number of MPs in Garri. Second, there are currently no models for material hazard rating based on the findings of toxicity tests. The chemical risk assessment was based on the hazard ranking of polymers and their monomers proposed by Lithner et al. [75]. The polymer risk profile described in this study could not accurately reflect the chemical risk associated with MPs.

Statistical analysis

Descriptive statistics was done using Microsoft Excel 2016. The data were analyzed using OriginLab Pro 8 and SPSS version 23 software package. Data were tested for normality and homogeneity of variances with the frequency test and q-q plots. Parametric tests were chosen since the data fulfill assumptions for ANOVAs. A one-way ANOVA was done to detect any significant differences (P < 0.05) between the garri samples for MPs and PTEs. Principal component analysis (PCA) and hierarchical clustering (HCA) was used to identify possible source(s) of contamination. As recommended by the Kaiser criteria, varimax rotation and retention of main components with eigenvalues greater than one were utilized for PCA while for HCA, the Euclidean distance was used for clustering. Pearson’s correlation analysis (CA) was conducted between the PTEs and MPs in the garri to evaluate a possible relationship between the two group of pollutants at 0.05 significance level.

Results and Discussion

Microplastics in garri

In this study, we isolated and characterized the various particles in garri sold in Nigeria and Japan. This study provided the first account of MPs in garri, a common staple food consumed by West Africans.

Quantity of microparticles and microplastics

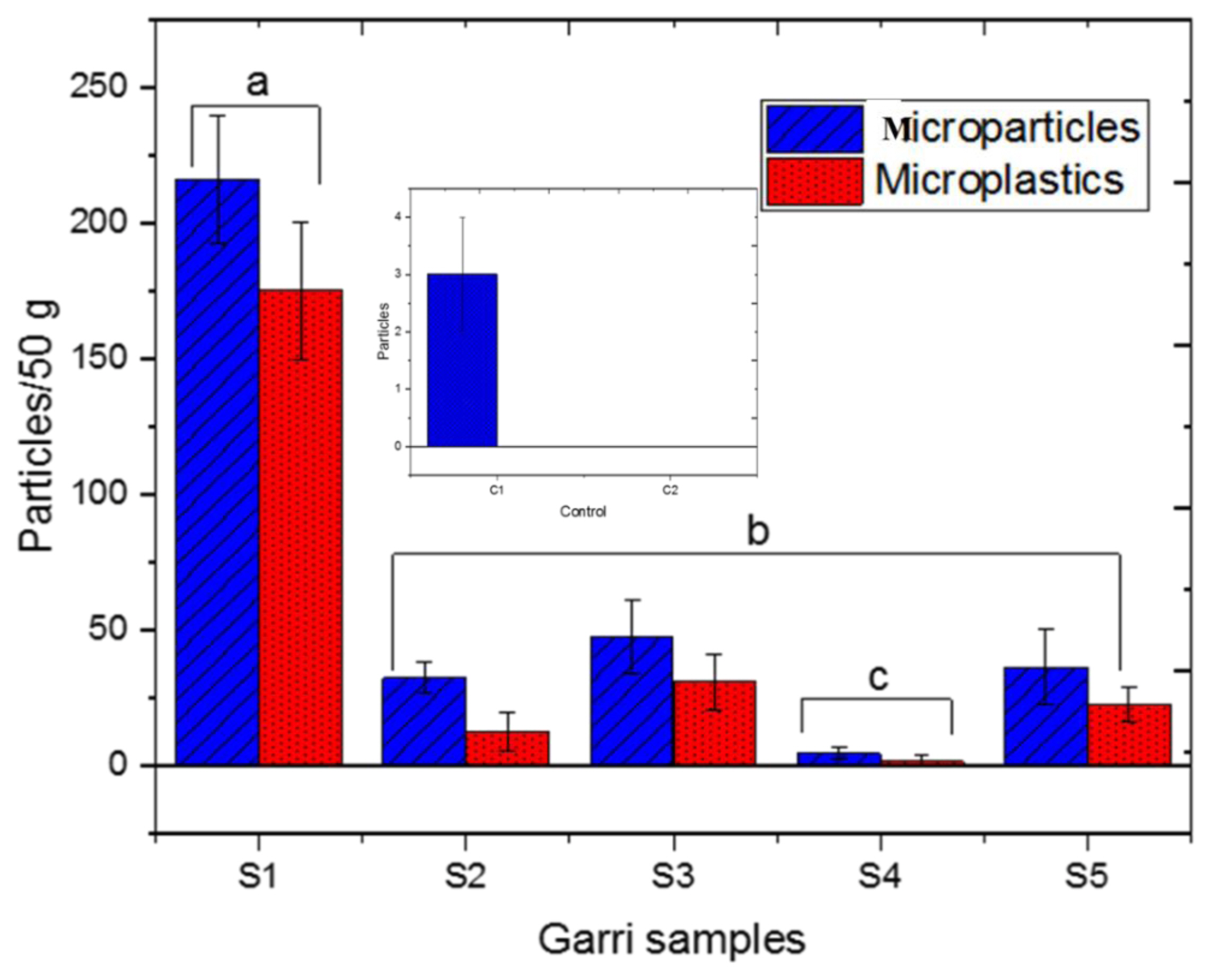

The distribution of microparticles (MPas) and MPs in garri samples and control is presented in Figure 4 and the data presented in Table S1. The total average MPas in all samples was 336.34 particles of which only 72.4 % was confirmed as MPs. The MPas were highest in S1, garri samples from open market and lowest in S4. Similar pattern was also recorded for MPs while no MPs was found in control samples. MPs recorded in S1 was 175.00±25.16 particles/50 g which was significantly different from other samples (p < 0.05). The high quantity of MPs found in this samples was attributed to the way it is been sold openly in markets or road sides and thus it is exposed to automobile exhaust emissions and atmospheric dusts or particles. Studies have shown that atmospheric dusts contain significant proportion of MPs and can be deposited in open food [35,36]. The remaining samples, which were packaged followed S3 (31.00±10.54 particles/50 g) > S5 (22.67±6.11 particles/50 g) > S2 (13.00±7 particles/50 g) > S4 (2.00±2.00 particles/50 g) respectively. S2, S3 and S5 showed no significant differences (p > 0.05) between them while S4 was significantly different from all samples (p < 0.05). Overall, it is suggested that packaged garri may be a safer option, as it is less exposed to atmospheric MPs.

Shape or morphology of MPs

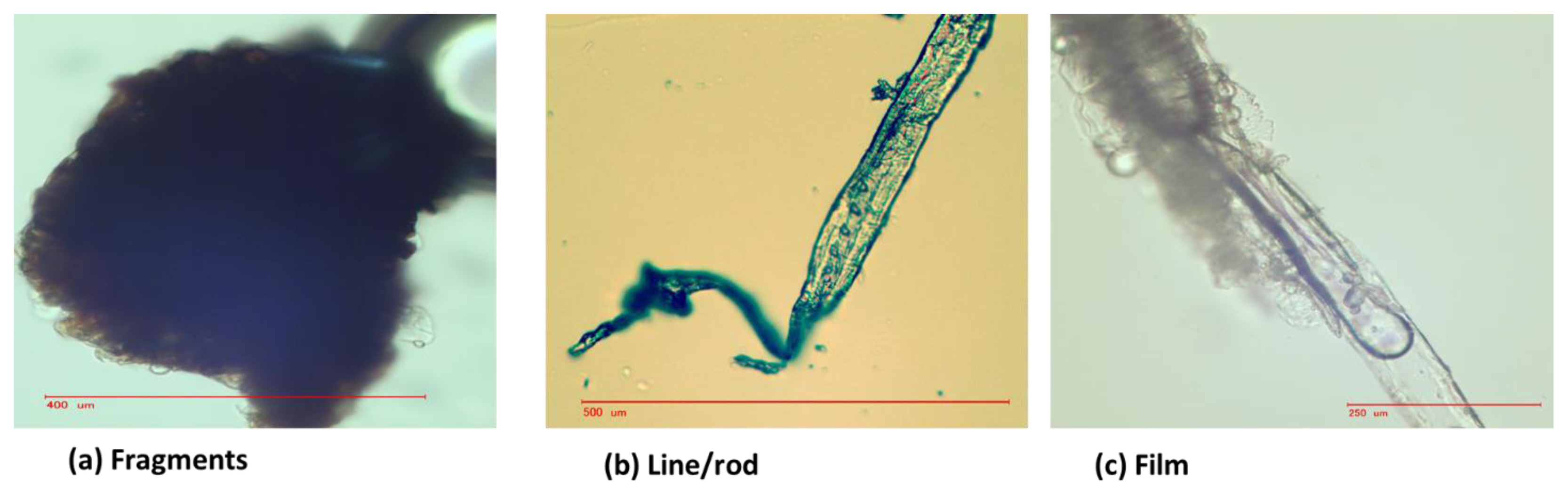

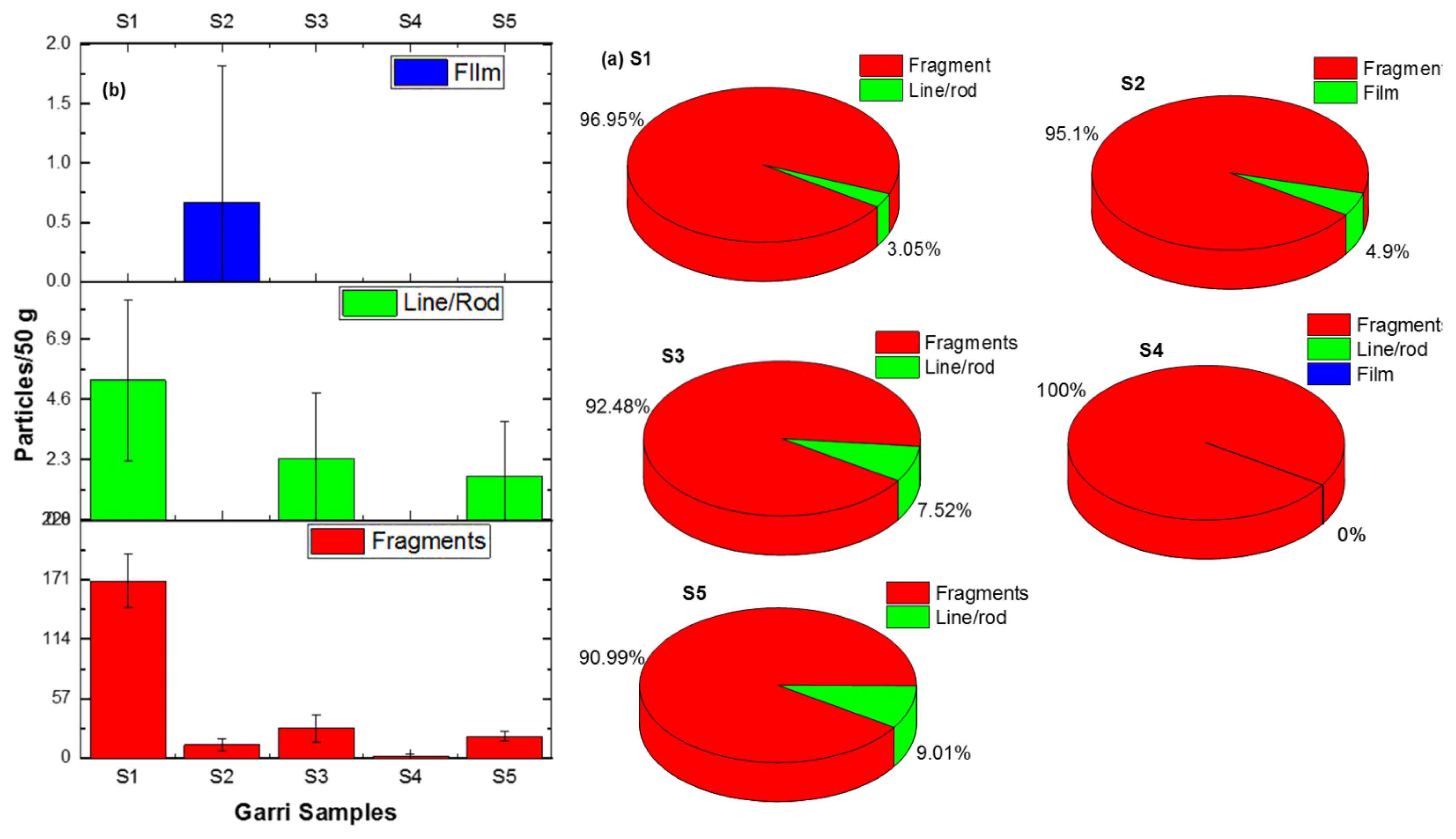

The analysis of the MPs from the fluorescence microscope showed mainly three shapes including fragments, line/rod and films (Figure 5).

For the fragment, the images show a fairly rough surface or jagged edges with cracks, indicating that it has been broken off from a large plastic. For the line, the image showed a shape like a thread or a long, narrow mark or stroke that is longer than it is wide while the film had a shape like a thin sheet. The distribution of the MPs based on the different shapes is presented in Figure 6. Overall, all samples contain high abundance of fragments > 90 % followed by film and line/rod at < 10 %. Fragment occurrence in the samples was in the following order; S1 (164.67±26.08 particles/50 g) > S3 (28.67±13.01 particles/50 g) > S5 (21±4.36 particles/50 g) > S2 (13±6 particles/50 g) > S4 (2±2 particles/50 g) while film was only found in S2 (0.67±1.15 particles/50 g or 4.9 %) (Figure 6b). There are no prior studies on garri for comparison. However, in foods, there have been many studies that have reported the presence of fragments in high proportion compared to other shapes [80, 81].

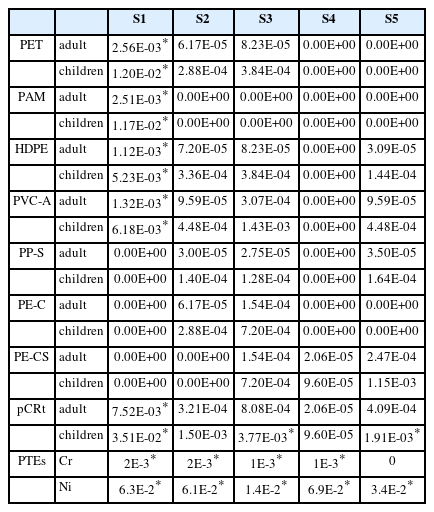

Identification of MPs

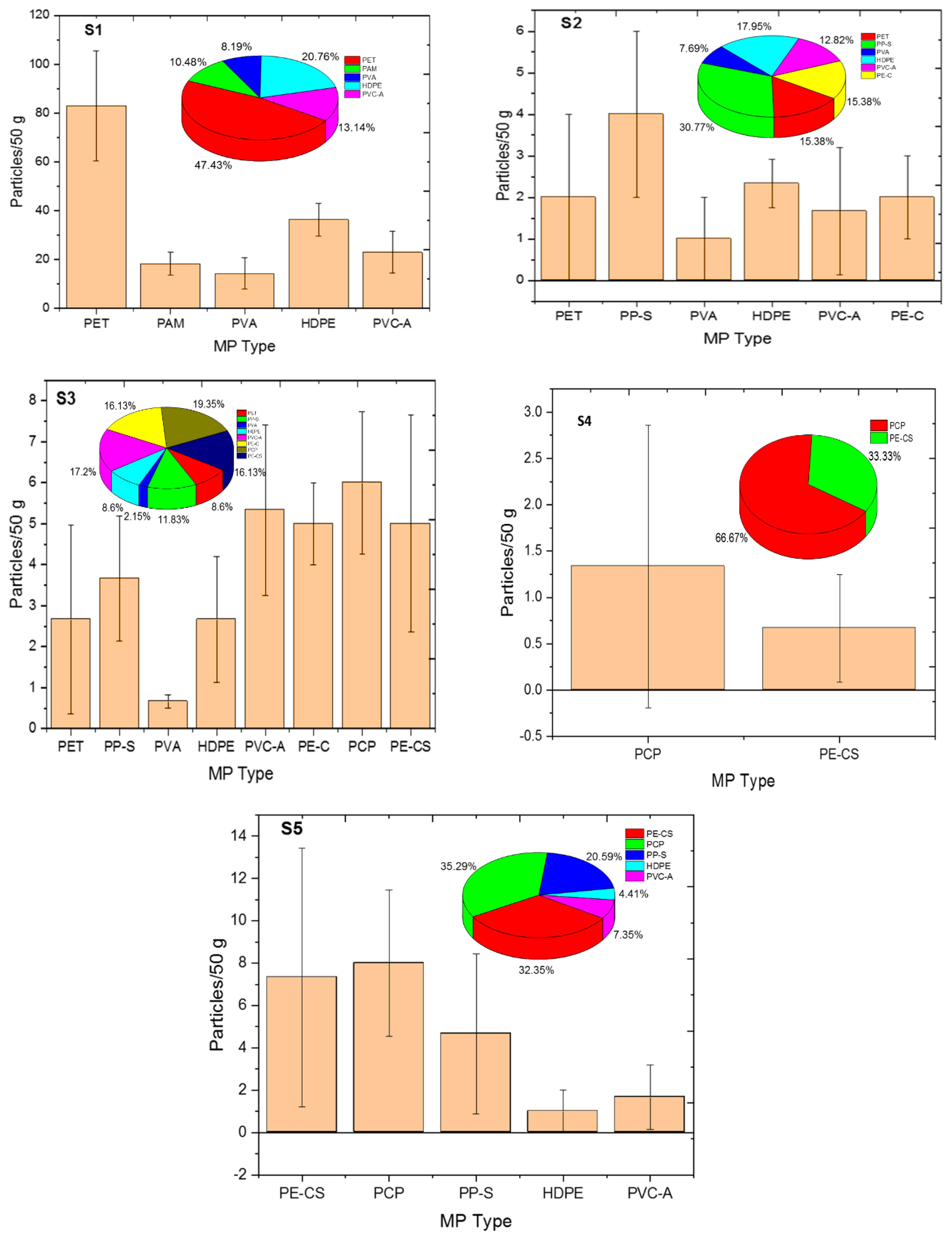

The chemical composition of MPas from the garri samples were identified by FTIR-ATR to determine the MPs type and results showed that 72.4 % was confirmed as MPs. The polymers which are reported from ATR-FTIR spectra (Figure 7) include PAM, PET, PVA, HDPE, PVC-A, PE-C, PP-S, PCP and PE-CS. The mean polymer concentrations were PET: 17.53, PAM: 3.67, PVA: 3.2, HDPE: 8.47, PVC-A: 6.33, PP-S: 2.47, PE-C: 1.4, PCP: 2.93 and PE-CS: 2.73 particles/50 g (Table S3) while the overall distribution was PET: 36 %, HDPE: 17 %, PVC-A: 13 %, PAM and PVA: 7 %, PE-CS: 6 %, PP-S: 5 % and PE-C: 3%.

FTIR-ATR spectra of different MPs types in garri samples. PAM: Polyacrylamide; PET: Polyethylene Terepthalate; PVA: Polyvinyl alcohol; HDPE: High density polyethylene; PVC-A: Polyvinyl chloride acrylonitrile; PE-C: Polyethylene chlorinated; PP-S: Polypropylene with silicate mix; PCP: Polychloroprene; PE-CS: Polyethylene chlorosulphonated.

However, the quantity and distribution of the different polymers in the different samples is presented Figure 8. In S1, PET, PAM, PVA, HDPE, and PVC-A was found. PET quantity was highest (83±22.52 particles/50 g) and thus was most distributed (47.43 %). Other MP types followed; HDPE (20.76 %) > PVC-A (13.14 %) > PAM (10.48 %) > PVA (8.19 %). In S2, PP-S and PVC-A was the most and least abundant with 30.77 % and 12.82 % respectively. Other detected MPs were HDPE, PET, PVA, and PE-C. In S3, nine distinct polymer types were identified including PCP (19.35 %), PET, HDPE, PP-S, PE-C, PVC-A, PCP, PE-S and PVA (2.15 %). In S4, only PCP (66.67 %) and PE-CS (33.33 %) was found while in S5, five polymers were identified in this order of abundance; PCP (35.29 %) > PE-CS (32.35 %) > PP-S (20.59 %) > PVC-A (7.36 %) > HDPE (4.41 %).

In this study, three types of synthetic rubber polymers were identified in all packaged garri samples that were sold in Nigeria and Japan. These polymers, known as PE-C, PCP, and PE-CS, are part of the synthetic rubber family and have a wide range of uses in various industries. They are known for their flexibility and softness, making them ideal for use in chemical processing, face mask manufacturing, and other applications that require fire resistance [37]. Additionally, they are also used as support systems for plants, keeping them firmly in place without causing any harm to the stem. PCP root coverings also serve an important function in hydroponic systems by obscuring light from entering the rooting chambers, thus promoting greater root development and preventing algae growth [38,39]. However, despite the many benefits of these polymers, recent studies have reported their high occurrence in the environment, raising concerns about their potential negative impact [40,41]. Overall, this study highlights the need for further research on the use and effects of synthetic rubber polymers in packaged food products and the environment.

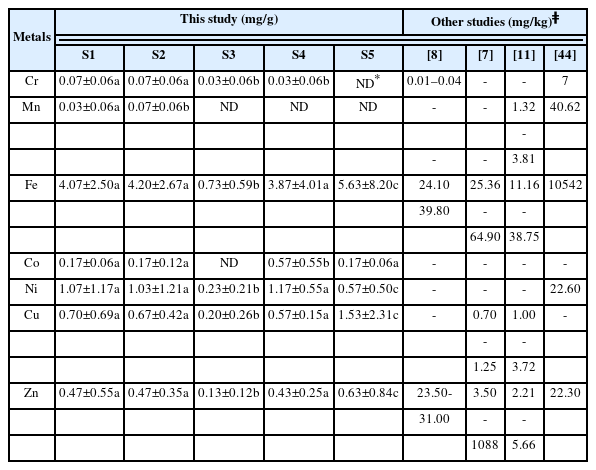

Concentration of PTEs in garri samples

Toxic elements exposure causes diminished growth and development, cancer, organ damage, and mortality [18, 25]. Iron (Fe), Nickel (Ni), Copper (Cu), and Zinc (Zn) are naturally present in foods and give some nutritional benefits to humans, but are hazardous if overabundance [11]. As shown in Table 2, the PTEs present in the 5 garri samples (S1 to S5) include; Chromium (Cr), Manganese (Mn), Iron (Fe), Cobalt (Co), Nickel (Ni), Copper (Cu), and Zinc (Zn). The concentration of PTEs in the samples ranged from ND to 0.07 mg/g for Cr and Mn, 0.73 to 5.63 mg/g for Fe, ND to 0.57mg/g for Co, 0.23 to 1.21 mg/g for Ni, 0.15 to 1.53 mg/g for Cu, and 0.12 to 0.63 mg/g for Zn. These concentrations were high when compared to other studies on garri in West Africa [7,8,11] but comparable with the recent study of Erukainure [42]. The high concentrations recorded in this study was attributed to the methodology. Previous studies have relied on the use of Atomic Absorption Spectrophotometer while we used X-ray fluorescence (XRF) technique similarly to the technique adopted by [42].

The results for the PTEs in all the samples were also found to be above the recommended maximum limits of 10 mg/100 g (Iron), 7.3 mg/100 g (Zinc) and 42.5 mg/100g (Copper) standard as specified by the Food and Agricultural Organization (FAO) and World Health Organization (WHO). Moremi & Jnr [43] reported a range of 12.08 to 28.80 mg/kg (Fe) for cassava tuber in the Eleme Local Government Area of River State. The trend for Fe observed in our investigation, which ranged from 730 mg/kg to 4200 mg/kg was significantly different, especially in the garri samples from Nigeria. However, the concentrations were lower than the maximum value of 10542 mg/kg recorded in Cassava tuber grown in crude oil-affected soil in Ikot Ada Udo, Ikot Abasi Local Government Area, Akwa Ibom State, reported by Osu [44].

The concentration of Zinc in all the samples ranged from 130–630 mg/kg and was above the FAO/WHO recommended standard. The result was equally higher than 3.20 – 6.59 mg/kg reported in cassava tuber in Eleme, Rivers state [43] and 5.33 mg/kg in cassava from impacted soil as well as 22.30 mg/kg in cassava tuber from crude oil impacted soil in Ikot Ada Udo, Akwa Ibom State [44]. Idakwoji [45] ascertained that zinc is essential for physiological and metabolic activities. Zinc, an enzyme cofactor and trace element, reduces lead toxicity. High concentrations may cause vomiting, gastrointestinal irritation (nausea, cramps, diarrhoea), weakness, anorexia, anaemia, slowed growth, hair loss, impaired food utilisation, and liver, brain, and renal dysfunction [46]. The maximum concentration of Cu ranged from 0.20 to 1.53 mg/g in the studied garri samples was higher than FAO/WHO intake recommendation and higher than the values of 0.87–1.23 mg/g reported in cassava tuber is some locations in Eleme local government area of Rivers state [43].

The general distribution of PTEs in samples followed; S1: Fe > Ni > Cu > Zn > Co > Cr > Mn; S2: Fe > Ni > Cu > Zn > Co > Cr > Mn; S3: Fe > Ni > Cu > Zn > Cr; S4: Fe > Ni > Cu / Co > Zn > Cr and S5: Fe > Cu > Zn > Ni > Co. Nevertheless, the sample of garri from Nigeria contain significantly (p < 0.05) higher amount of Cr (0.07 mg/g) when compared to (0.03 mg/g) from the samples of S3 and S4 from Japan. Although, Mn was not detected in the samples from Japan, S1, which is the sample from open market and S2, a packaged sample from Nigeria contain 0.03 mg/g and 0.07 mg/g respectively, which was significantly different (p < 0.05). The white garri sample from Japan, S3 and S4 has lower amount of Fe compared to the white garri samples S1 and S2 from Nigeria and S5, the yellow garri sample from Shinjuku, Japan. The Co content of 0.017 mg/g of the samples from Nigeria is also similar to that in the yellow sample of garri from Japan, however, sample S4, is found to have a slightly higher concentration of Co at 0.57 mg/g. For nickel, S3 sample of white garri from Japan has the lowest content, only S4 was found to contain similar amount with the two samples from Nigeria. Similar to the findings from Awoyale et al., (2017), garri sample S5 which is a yellow garri, have the highest Fe (5.63 mg/g), Zn (0.63mg/g) and Cu (1.53mg/g) contents. The amount of Cu and Zn in sample S3 of white garri from Japan is notably low at 0.20 mg/g and 0.13 mg/g, compared to S1, S2 and S4. It has been reported that metals such as Fe, Cu, and Zn are essential components of numerous alloys, wires, and car tyres, and that they are typically released to the roadside environment due to mechanical abrasion and natural wear and tear [14]. This indicated that the yellow garri with the highest concentrations of these metals may have either been roasted along a roadside, a market with substantial automobile traffic, or spread and sun-dried by the vehicular road side for secondary drying during processing and preparation.

Source analysis of MPs and PTEs

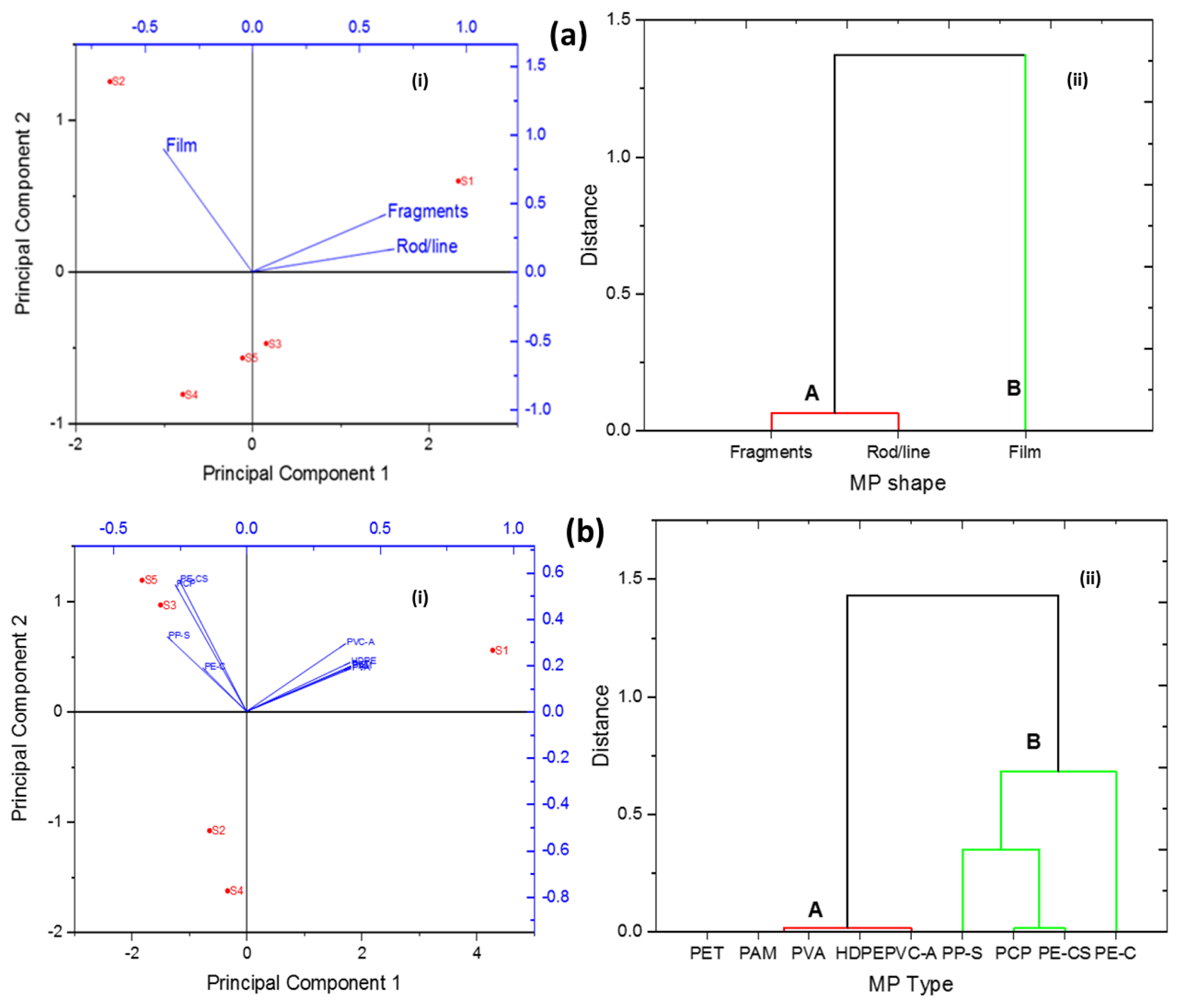

Principal Component (PCA) and hierarchical clustering (HCA) analysis were conducted to appraise the source(s) of MPs and PTEs in the garri samples. PCA is a data dimension reduction strategy that uses a small number of independent variables (called “principal components”) to explain the bulk of the variance in the data [18]. To get the first principle component that accounts for the largest amount of variance in the original data, the technique uses an orthogonal transformation strategy. The next step is to identify each subsequent component by restricting it to be orthogonal to all prior components. It is usually done using eigenvalue decomposition as part of a matrix operation. The data set’s major components are the eigenvectors having the highest eigenvalue (> 1) [46]. On the other hand, HCA produces a dendrogram, a visual representation of a hierarchical grouping of enormous quantities of information. Major clustering groups may be assessed using Euclidean distance. The horizontal axis of the dendrogram depicts clusters, while the vertical axis reflects dissimilarity or distance between clusters. Each run in a dendrogram starts in its own cluster, and at each step, the two most similar clusters merge to form a single new cluster [46]. The results for PCA and HCA for the MPs shape and polymer types are presented in Figures 8a and b while for the PTEs in Figure 9.

MPs

In the PCA for shape (Figure 9ai), two components were extracted i.e PC1 and PC2 which accounts for 72.54 % and 26.16 % of the total variance. Fragments and line/rod are in PC1 with component factor of 0.62 and 0.66 respectively and thus come from similar source(s) while film was in PC2 with component factor of 0.89. PC1 sources could come from the production process which includes the peeling of cassava and grating in a locally constructed motorized cassava grating equipment, the fermentation before dewatering using a manual screw press and frying into garri. Another possible source could be from exposure to atmospheric dusts. However, the PC2 suggests packaging as the likely source of contamination. For the HCA (Figure 9aii), the cluster formed was akin to the PCA. The fragments and line/rod showed very small distance between them while film showed large distance from the two shapes. The cluster represent sources described in the PCA.

For MP types (Figure 9b), the PCA showed PC1 and PC2 accounting for 67.92 % and 18.01 % of the total variance. PC1 consisted of PET, PAM, PVA, HDPE and PVC-A while PP-S, PE-C, PCP and PE-CS are in PC2. Similarly, two HCA, showed two cluster A and B (Figure 9bii). However, within the clusters some plastic polymers still had smaller distance between them. For examples, PCP showed very small distance from PE-CS in cluster B. This observation also agrees with the PCA and attributed to the chemical structures of these plastics. PC1 and/or cluster A is attributed to the production processes and atmospheric deposition while PC2 and/or cluster B is attributed to packaging process. The polymers in PC1 are quite common in the Asian and African environment [48,49]. In Nagpur, India, Narmadha [50] studied roadside suspended dust from urban and rural regions and discovered HDPE, rubber fiber, polyaniline, and chlorinated polyvinyl chloride. PP and PE were often the most studied MPs in Dongguan City Air Fallout [51]. PET, PE, polyacrylonitrile, ethylene vinyl acetate, and PAM, were among the suspended air microplastics in Shanghai [52]. However, the polymers in PC2 are part of the synthetic rubber family, which has a broad range of uses in chemical processing, face mask manufacturing, safety gloves and other fire-resistant applications [37,53,54]. Therefore, they can easily be emitted into the packaged garri during packaging process in the factory. These findings suggest that efforts to reduce contamination in garri should focus on improving production processes and packaging methods.

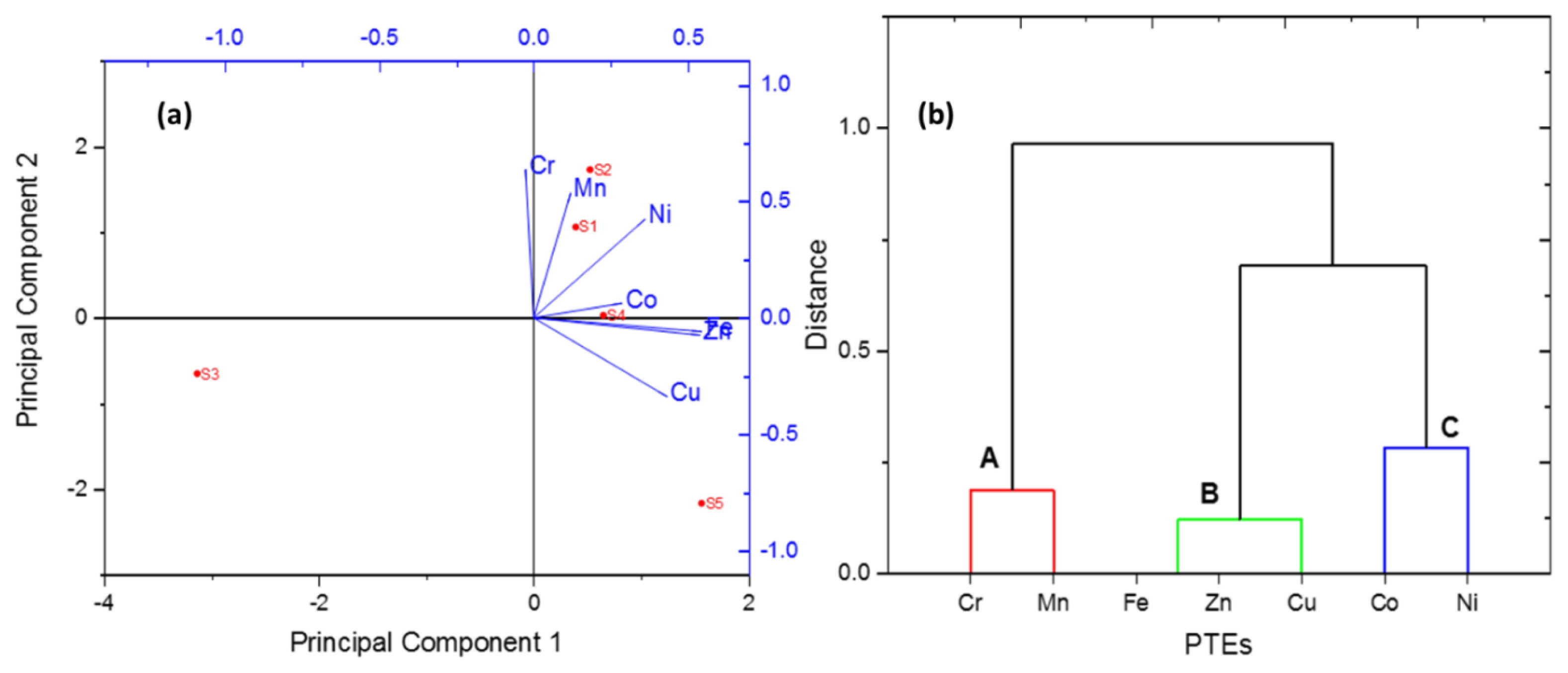

PTEs

For the PTEs, the PCA and HCA generally showed three main clusters or components (PC 1, PC 2 and PC 3) accounting for 46.87 %, 33.06 % and 18.34 % of the total variance respectively based on eigen value greater than 1 (Figure 10). PC 1 or cluster B contain Cu, Zn and Fe, which source is geogenic [44] and anthropogenic particularly from the use of iron pan for frying the garri during production [55] or from atmospheric deposition during vending in markets [8]. PC 2 or cluster A contains Cr and Mn, which could be from the frying process using high energy/combustion sources such as firewood, coal and fuel oil burning [14,56] while PC 3 or cluster C contains Co and Ni, attributed to cassava peel waste incineration common in processing sites [55].

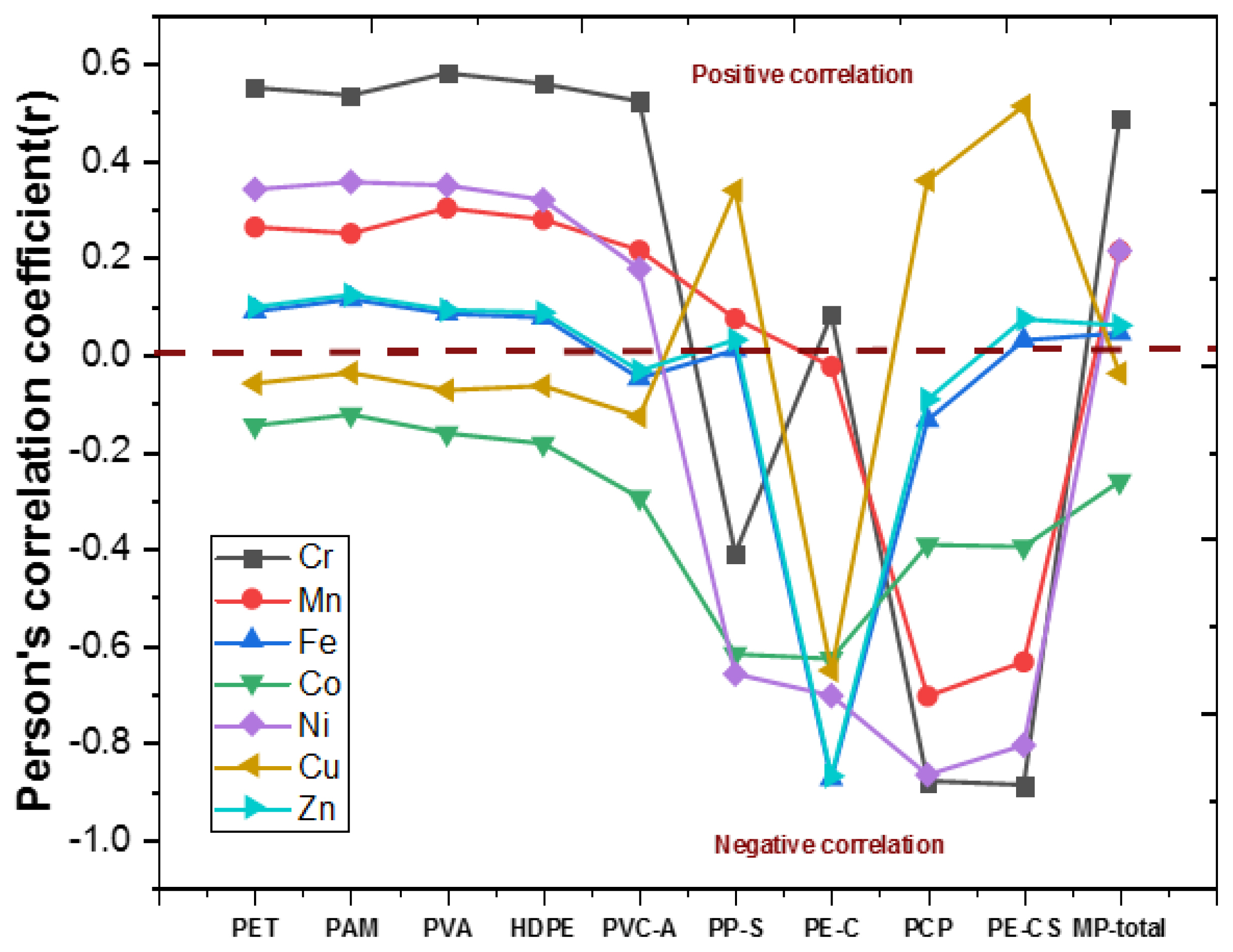

Correlation between MPs and PTEs

MPs can serve as a source, vector and sink for PTEs through leaching and adsorption processes [18]. Therefore, both pollutants exhibit some kind of relationship between them and influence their toxicities. However, in generally, polymers with varying surface textures and, as a result, have variable affinities for contaminants. In this study, the relationship between PTEs and MPs in the garri samples were examined by correlation analysis and the result is presented in Figure 11.

Correlation between PTEs and MPs in garri. Positive correlation indicates an increase in MPs concentration will corresponds to an increase in PTEs concentration while negative correlation indicate increase in MPs will result to reduction in the concentration of PTEs

The relationship varied by PTEs and MPs types with either positive or negative correlation. A positive correlation between microplastics (MPs) and potentially toxic elements (PTEs) means that as the concentration of MPs increases, so does the concentration of PTEs. On the other hand, a negative correlation between MPs and PTEs means that as the concentration of MPs increases, the concentration of PTEs decreases and vice versa. However, the extent of correlation is determined by the correlation coefficient (r). When r ranged from 0 to 0.29; 0.3 to 0.49; 0.5 to 0.69 and 0.7 to 0.99, it is considered poor, weak, moderate and strong correlation respectively [82]. The positive correlations were generally poor to moderate. Cr showed moderate positive relationship with PET, PAM, PVA, HDPE, PVC-A and total (mean) MP concentrations. For the same MPs, Mn and Ni showed weak positive correlation. Co relationship with all MPs types was negative which is similar to Cu except for PP-S, PCP and PE-CS respectively which was positively weak to moderate. Similar relationships have been obtained for some of the PTEs and MPs types in other studies conducted in the environment [18,83].

Health risks assessment of MPs and PTEs in garri

Estimated daily intake

MPs

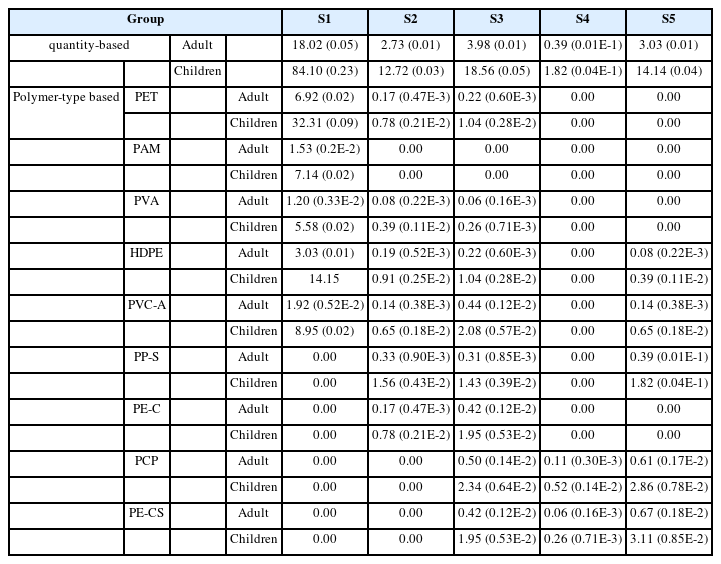

The particle size of the microplastics (MPs) in the study ranged from 12 to 500 μm, which is small enough for humans to ingest. Table 3 displays the estimated daily intake (EDI) of MPs from consuming garri samples for both adults and children. The EDIs are generally low, indicating that daily consumption of the samples is not harmful. Recent study has also found low intake of MPs from consuming bottled water [17]. However, consuming the garri samples over a prolonged period of time (a year) results in a high intake of MPs due to the quantity and types of MPs present in the samples, as shown in Table 3.The yearly intake based on quantity of MPs followed; S1 > S3 > S5 > S2 > S4 for both adult and children. In terms of specific polymer type, all identified polymer types in S1 was > 1 while only HDPE and PE-C for children in S3 (1.04 and 1.95 particles/g-year respectively) were > 1. Furthermore, PCP and PE-CS in S3 and S5 showed high yearly intake for children 2.34, 2.86 particles/g-year (PCP) and 1.95 and 3.11 particles/g-year (PE-CS) respectively. Based on these results, high exposure to MPs toxicity is higher in S1 (unpackaged garri sample from open market) compared to packaged samples. In general, the EDI findings found that children consume more MPs than adults, which agrees with previous reports [17,57]. It is not known how long MPs stay in the body until they are eliminated, hence, information on the potential risks that MPs pose to the health of both children and adults is still very sketchy. However, meta-regression assessments of the toxicological effects of MPs exposure in human cells showed that even at low, ecologically relevant quantities of MPs, cell viability and cytokine release were negatively affected [58].

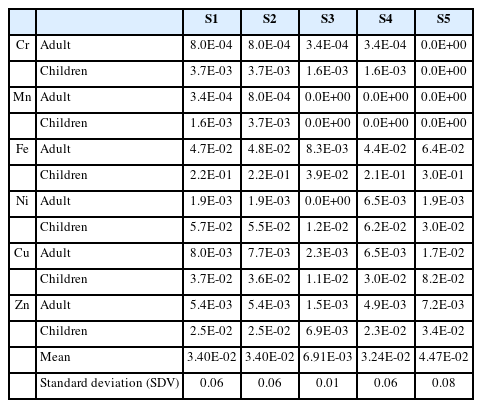

PTEs

The estimated daily intake of PTEs from the consumption of garri to both adult and children is presented in Table 4. All metals showed low daily intake for both adult and children, which followed the order; Fe > Cu > Zn > Ni > Cr > Mn. The acceptable intake of metals via garri consumption for some metals provided by FAO/WHO was 0.0015 mg/day, 15 mg/day and 10–15 mg/day for Cr, Fe and Zn [8]. In comparison with these limits, only Cr in children showed higher intake. These results for ED1s also revealed higher intake for children than adult. Higher exposure of children to toxic metals has been reported in many studies [46,59]. When considering intake of PTEs by samples, the highest daily intake was recorded for S5 (yellow garri; 4.47E-02±0.08 mg/g day) and the least for S3 (6.91E-03±0.01 mg/g day) (Table 4).

Non-carcinogenic health risk assessment

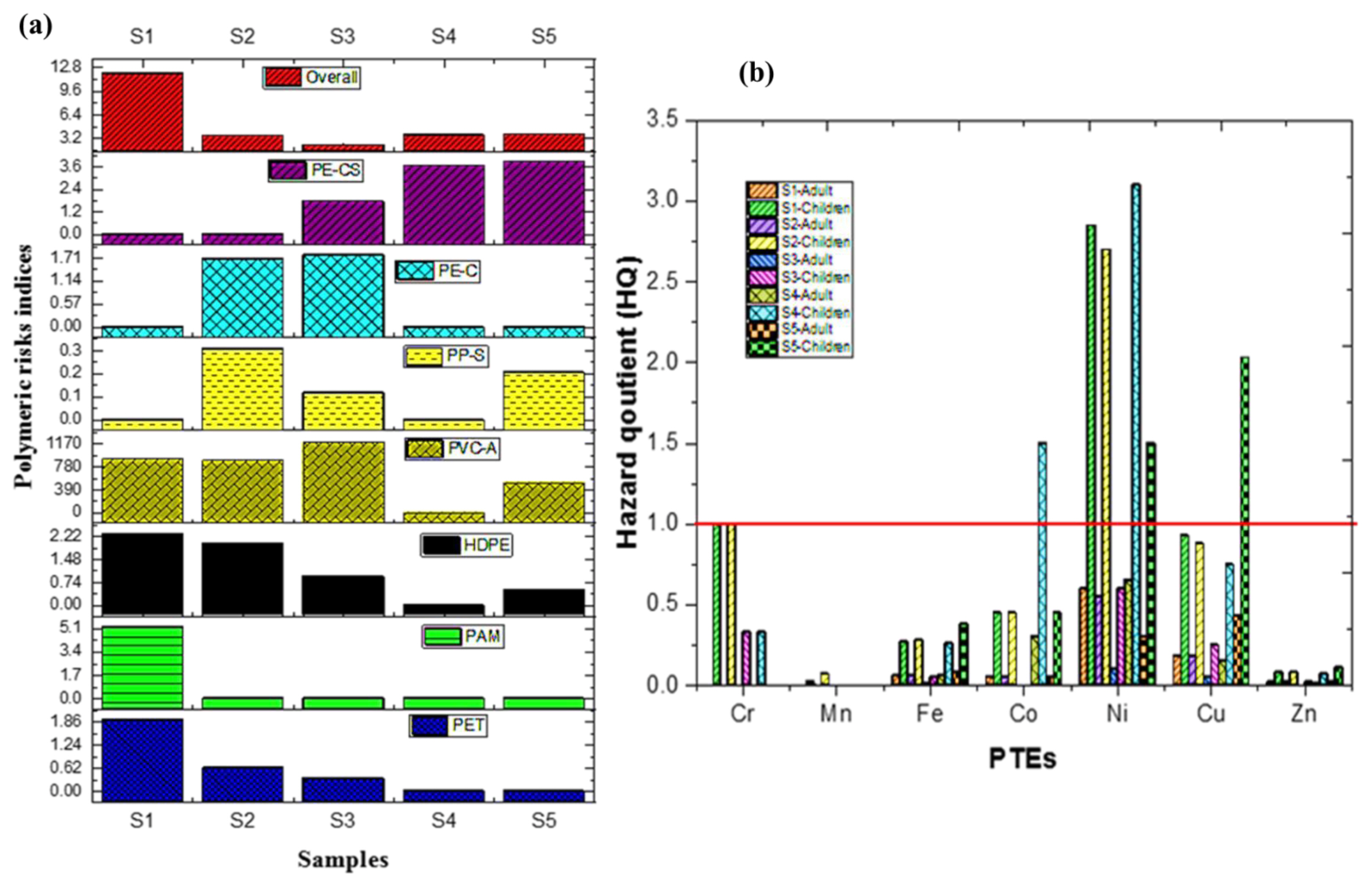

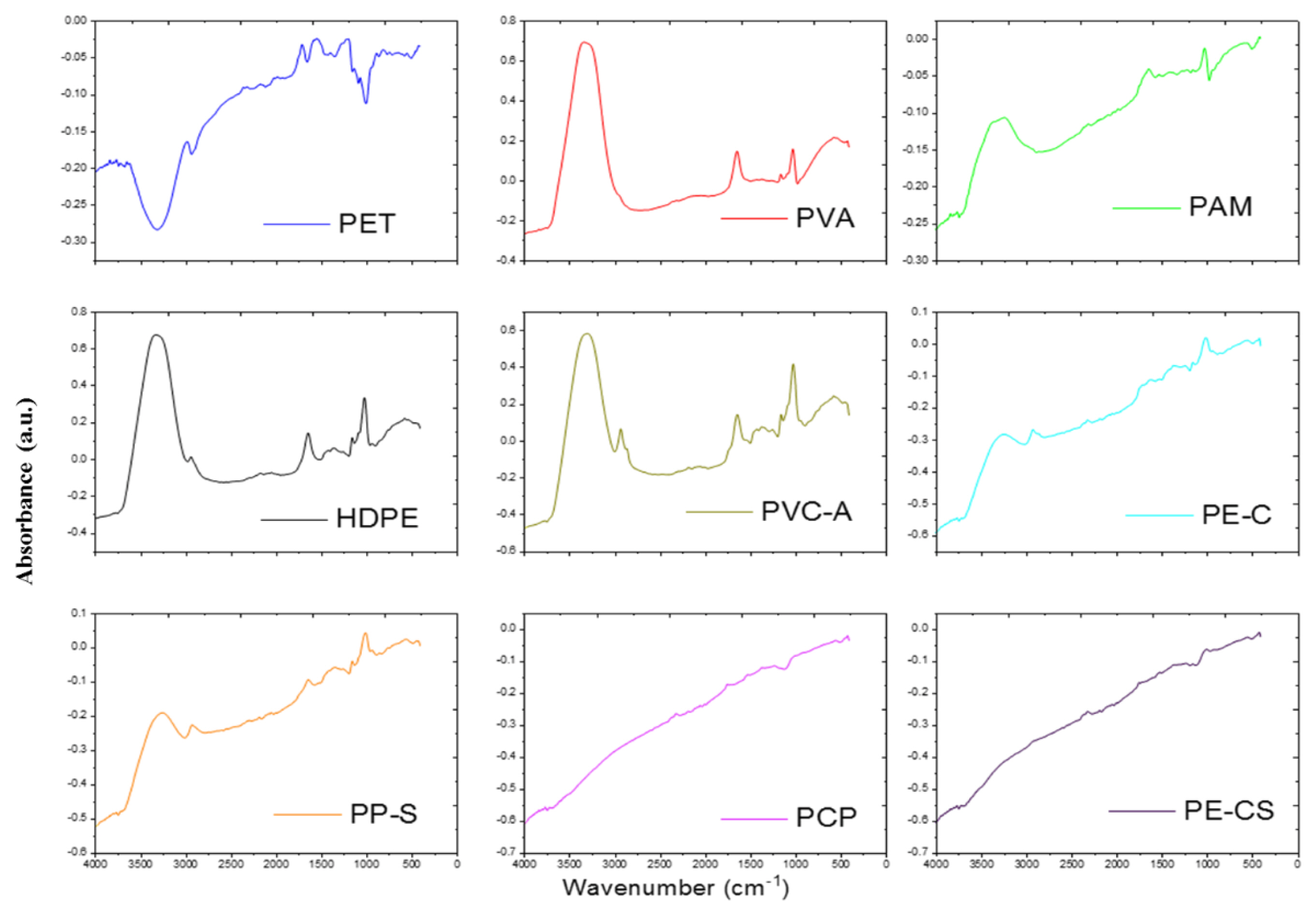

MPs polymeric risks

Figure 12a shows the findings for the MP polymer risk indices (pRi) and pollution risk index (overall). MP polymeric risks indexes was calculated as non-carcinogenic health risks posed by MPs depending on their composition. The pRi are classified as low when less than 150, medium when 150–300, considerable when 300–600, high 600–1200, and very high when more than 1200 [47,60]. Following the categorization, all samples revealed low risks for all MP types, with the exception of PVC-A, which was considerable in S5 (511.55) and was high in other samples. This is owing to the presence of PVC and its high hazard rating [17,75]. Plastics containing vinyl chlorides are often times considered poison plastics due to their impact on health. Some of the non-carcinogenic effects include immune system damage, hormone disruption, dizziness, drowsiness, headaches and liver damage [61]. However, for each sample, the polymeric risks index (overall) was very low and followed the order; S1 (12) > S5 (3.75) > S4 (3.67) > S2 (3.55) > S3 (2.29). There was no definite trend, but samples from Nigeria (West Africa) had higher risks index compared to those collected in Japan (3.24). Since there is no investigation on MPs contamination in garri samples yet, the results of this study could not be compared with any other study.

PTEs

The hazard quotient (HQ) was used to calculate the non-carcinogenic risk of PTEs from garri consumption to adult and children. When HQ ≤ 1 is considered safe for health consequences while HQ > 1 is considered dangerous. Figure 12b shows the HQ of Cr, Mn, Fe, Co, Ni, Cu, and Zn for children and adult. All samples had HQ values of less than 1.0 for adults, indicating that these samples have no non-carcinogenic health effects on adult consumers. However, for children, the HQ values of Co in S4 (1.5), Ni in S1 (2.85), S2 (2.70), S4 (3.10), and S5 (1.50) and Cu in S5 (2.03) all exceeded critical values (HQ > 1), indicating non-cancer concerns. Mental retardation, neurocognitive abnormalities, behavioral disorders, respiratory problems, and cardiovascular ailments are among the adverse effects of these elements on children’s health [62]. PTEs need special consideration due to their high toxicity potential, broad usage, and ubiquity. However, comparing with other studies on garri, there was no non-cancer risks from consumption [8,11].

Carcinogenic health risks

Carcinogenic risks (CR) are calculated as the chance of a person developing cancer over their lifespan. The ingestion CSF was used to assess the lifetime risk of the exposed populations as a result of garri consumption. The carcinogenic risks on MPs and PTEs from garri consumption is presented in Table 5. The results were compared with the U.S Environmental Protection Agency acceptable cancer risk range which is between 1×10−6 to 1×10−4 [63]. In S1, all MPs type detected (PET, PAM and HDPE) showed significant carcinogenic risks to both adult and children. PET contain phthalates, which may leak into the body if consumed. Phthalates are a class of synthetic endocrine disruptors that have been linked to malignant tumors, birth abnormalities, and other developmental problems [64]. PAM has been linked to endometrial and ovarian cancer risk [65,66]. In males, it may also raise the risk of cutaneous malignant melanoma [67] as well as incidence of lymphatic cancers such as multiple myeloma and follicular lymphoma [68]. Results also showed only PVC-A (1.43E-03) showed carcinogenic risks to children in S3. Vinyl chloride (VC) in PVC-A causes cancer in animals and humans. It is highly linked to liver cancer, especially liver angiosarcoma (LAS), a malignant tumor of liver endothelial cells [69]. VC also causes hepatocellular carcinoma (HCC), a malignant liver tumor [70,71]. However, total CR from the summation of individual polymer risks was significant in S1 to both adult and children while S2, S3 and S5 were significant to only children and S4 showed no carcinogenic risks to both adult and children (Table 5). For PTEs, both Cr and Ni CR values surpassed the safe limit of danger. The CR values of all samples (except S5) were higher than the threshold risk level (CR > 10−6), indicating a possible cancer risk from consuming contaminated garri. Cr and Ni have been linked with increased risk of lung cancer.

Conclusions

In garri samples gathered from Nigeria and Japan, potential toxic elements (PTEs) and quantities and kinds of microplastics (MPs) were investigated. The amount of microplastic in garri depends significantly on how it is packaged for sale. The quantities of microplastics were found to be highest in openly vended garri from Nigeria. The concentrations of PTEs were high in all samples. However, their estimated daily intake was low for both adult and children, which was also similar for MPs. The yearly estimated intake of MPs was highest in openly vended garri from Nigeria for both adult and children and high exposure to MPs toxicity is also high in comparison to packaged samples. The sources of MPs and PTEs were mainly from the production process of cassava into garri, atmospheric dusts and during packaging. The non-carcinogenic risk for all samples was low for MPs, while only high for PTEs such as Co, Ni and Cu in some specific samples for children. The MPs in openly vended garri from Nigeria, Ni and Cr in all sample pose carcinogenic risks to both adult and children. Garri sold in public places should be consumed with caution. In addition, efforts should be made to enhance the overall cassava-based garri production process by steering clear of substances that can possibly include MPs.

Acknowledgement

Kola-Adepoyigi Adeyosola is acknowledged for her help in collecting garri sample from Abuja, Nigeria and transported to Japan.

This study was partially supported by the Special Funds for Innovative Area Research (No.20120015, FY 2008-FY2012) and Basic Research (B) (No. 24310005, FY2012-FY2014; No.18H03384, FY2017-FY2020; No.22H03747, FY2022-FY2024) of Grant-in-Aid for Scientific Research of Japanese Ministry of Education, Culture, Sports, Science and Technology (MEXT) and the Steel Foundation for Environmental Protection Technology of Japan (No. C-33, FY 2015-FY 2017)

Notes

There is no conflict of interest to declare

CRediT author statement

CEE.: Conceptualization, methodology, validation, formal analysis, data curation, writing—original draft preparation, writing—review and editing, QW: formal analysis, resources contribution, supervision, funding acquisition, data curation, writing—original draft preparation, writing—review and editing; RMH: formal analysis, data curation, writing—original draft preparation; SL: writing—review and editing; WS: writing—review and editing; LD: writing—original draft preparation; writing—review and editing and ROB: formal analysis, data curation, writing—original draft preparation.

Supplementary Material

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.